Chinchero International Airport | Chinchero – Cusco, Perú

Building the Future: Chinchero International Airport Rises to New Heights

Chinchero – Cusco, Perú

A Transformative Infrastructure Project

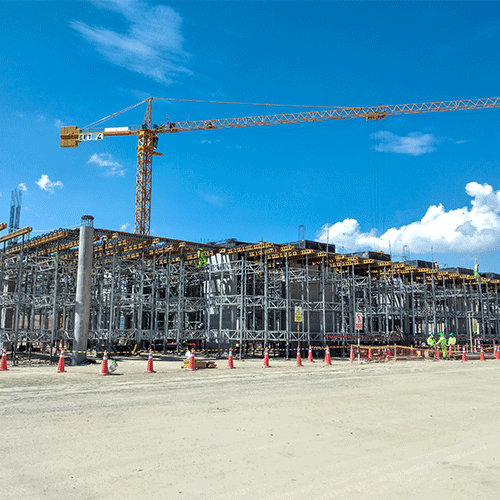

The construction of the new Chinchero International Airport, located 25 miles (40 km) from Cusco, Peru, marks a transformative moment for the region. Designed to replace the existing Alejandro Velasco Astete Airport, the new terminal will be eight times larger and serve as a modern hub for international travel. Despite the challenges of building at 12,500 ft (3,800 meters) elevation and managing seasonal rains from January to March, the airport will significantly enhance regional connectivity and unlock new economic opportunities for Peru’s historic Cusco region.

International Collaboration and System Selection

The Natividad de Chinchero Consortium—composed of construction leaders from Korea, China, Mexico, and Peru—selected EFCO based on its robust equipment, responsive field service, and engineering expertise. EFCO collaborated closely with the consortium to develop customized forming solutions tailored to the terminal’s unique shape and construction sequence. HAND-E-FORM® was used for walls and columns, while E-Z DECK® and E-BEAM® provided efficient shoring across 540,000 sq. ft (50,000 sq. meters). With a T-shaped terminal layout and consistent 23 ft (7-meter) heights, the project demanded reliable forming systems that could deliver consistency and speed.

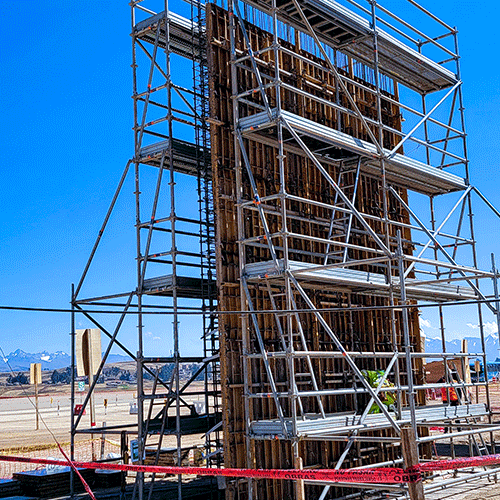

HAND-E-FORM: Versatility at Height

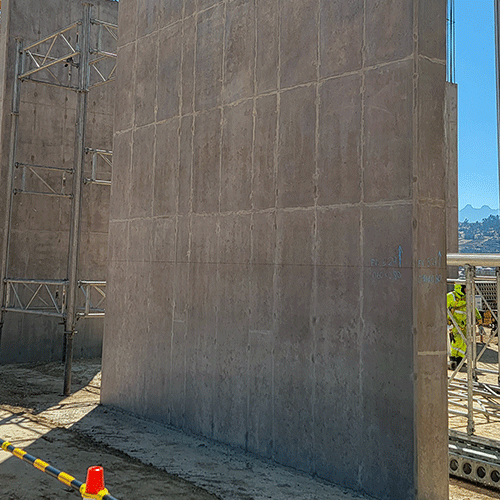

EFCO’s HAND-E-FORM® system supplied approximately 10,250 sq. ft. (950 m²) of formwork—an ideal solution for job sites with limited lifting equipment. Its lightweight handset design enabled workers to lift and position components manually, eliminating crane dependency. The system allowed the team to complete four columns and three walls daily in 6′-6″ (2000 mm) lifts. HAND-E-FORM® performed exceptionally on walls ranging from 16″ to 20″ (40–50 cm) thick, delivering smooth concrete finishes in single pours while maintaining speed and efficiency in a challenging environment.

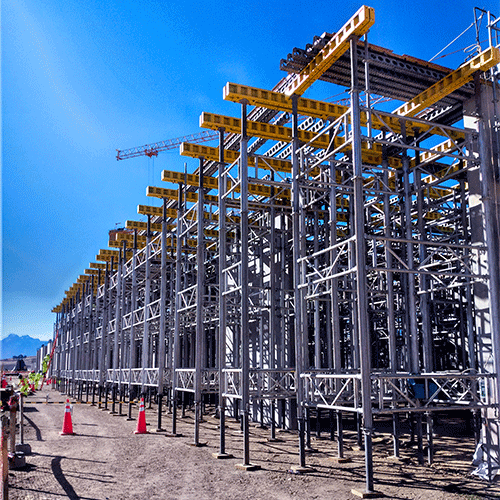

E-Z DECK: Maximizing Efficiency with Minimal Components

To support the project’s complex beam-and-slab design, EFCO’s E-Z DECK® system delivered a highly efficient solution. The 32′-10″ x 29′-6″ (10 m × 9 m) structural grid was divided into nine segments by secondary beams, requiring strategic shoring. The engineering team achieved stable, geometry-conforming support using fewer components by leveraging the high load capacity of EFCO posts and joists. This innovative setup reduced freight costs by 20% and lowered labor requirements for equipment cycling by 15% compared to other systems.

Overcoming Seasonal Challenges

EFCO’s flexible system design proved invaluable during Peru’s rainy season. Engineers planned to reuse the longest posts from the 23′-8″ (7.20 m) first-level heights in the 17′-9″ (5.40 m) second-level sections, creating efficient equipment rotation cycles. This planning enabled the consortium to maintain momentum and exceed productivity expectations during favorable weather, helping offset slower periods.

More Than Equipment: EFCO’s Real Advantage

EFCO’s advantage lies in more than just equipment—it’s the combination of engineered solutions, deep field experience, and a commitment to problem-solving in real time. Every EFCO system used on this project was backed by personalized service, including on-site training, engineering consultation, and field support throughout each construction phase.

With formwork systems designed for durability, modularity, and efficient reuse, EFCO helped the consortium reduce equipment turnover and simplify logistics at high elevations, where every lift counts. Using preassembled work decks, strategic staging guidance, and customized equipment configurations ensured safe, consistent productivity across changing jobsite conditions.

EFCO proved to be a dependable strategic partner. We would work with them again on similar projects. We give EFCO the highest possible endorsement for successfully completing concrete construction in challenging environments.

-Giancarlo Barrios, Construction Manager

Why the Natividad de Chinchero Consortium Chose EFCO

The consortium’s selection of EFCO delivered the Lowest in-Place Concrete Cost through superior engineering and unwavering service. When plans changed shortly before construction phases began, EFCO quickly adapted to updated assembly requirements. This responsiveness, paired with a solution requiring fewer components while achieving greater productivity, reflects EFCO’s commitment to its core values of Quality, Integrity, Innovation, and Super Service.

CONSORCIO NATIVIDAD DE CHINCHERO

Gerardo Pucciarello, Project Manager

Jose Luis Gandolfo, Project Manager

Giancarlo Barrios, Construction Manager

Cesar Estrada, Project Engineer

EFCO FORMWORK Specialists – PERÚ

Carlos Vizurraga, Territory Manager

Ronald Ruiz, Field Service

Daniel Fernandez, District Engineer

Carlos Vicente, District Engineer

Trusted Formwork Partner

Why Trust Anyone Else?

We are ready to assist you in finding the best forming and shoring solutions for your construction projects.